Environmental Approval

Environmental Approval

- Installation and Change of Air Pollutant Emission Facility [Air Environmental Conservation Act]

- Installation and Change of Volatile Organic Compounds Emission Facility [Air Environment Conservation Act]

- Installation and Change of Wastewater Emission Facility [Water Environment Conservation Act]

- Report on the installation of other water sources [Water Environment Conservation Act]

- Installation and Change of Odor Emission Facility [Act on the Prevention of Bad odor]

- Installation and change of noise and vibration emission facility [Noise and vibration management method]

- Installation and Change of Waste Treatment Facilities [Waste Management Act]

- Hazardous Hazard Prevention Plan [Industrial Safety and Health Act]

Preparation data for approval

- Copies of existing certificate of completion of report or permits (excluding initial reporting and authorization)

- One copy of Certificate for Business Registration

- Production process chart and process description

- Raw material usage and product production volume

- Material Safety Data Sheet for used material (MSDS)

- Drawings of business sites, layout of machinery, and discharge facilities

- 1. Approval Schematic Diagram

Manufacturing Hazard Prevention Plan

- 1. Laws (Article 48 of the Industrial Safety and Health Act)

- When installing, transferring, or changing all construction, machinery, apparatus, and facilities directly related to the production process of the products, the business owner as prescribed under the Presidential Decree shall draw up a plan concerning the prevention of harmful effects and risks as provided under this Act or the orders under this Act and submit it to the Minister of Employment and Labor as provided under the Employment and Labor

-

The application of Article 1 shall be made to owners who wish to install, transfer or change major structural parts of machinery, apparatus, and equipment, which are any of the following, under the Employment and Labor Ministry Ordinance:

1. Requiring harmful or dangerous work

2. Using in harmful or dangerous places

3. Using to prevent health problems

- 2. Types of businesses subject to submit hazardous risk prevention plan

- A business that is equivalent to any of the following is a business that has an electrical contract capacity of more than 300kW.

- Major structural change

- Modification, replacement, and extension of equipment or machinery related to production of electrical charge capacity exceeding 100 kW

- Changing the layout of facilities or machines by unit process

| Business Type | Business Code |

|---|---|

| Metalworking products (excluding machinery and furniture) manufacturing | 25*** |

| Nonmetallic mineral products manufacturing | 23*** |

| Other machinery and equipment manufacturing | 29*** |

| Automobile and trailer manufacturing | 30*** |

| Food manufacturing | 10*** |

| Rubber and plastic products manufacturing | 22*** |

| Timber and wood products manufacturing | 16*** |

| Other products manufacturing | 33*** |

| Primary metal manufacturing | 24*** |

| Furniture manufacturing | 32*** |

| Chemicals and chemical products manufacturing | 20*** |

| Semiconductor manufacturing | 261** |

| Electronic components manufacturing | 262** |

- 3. Types of facility subject to submit hazardous risk prevention plan

- 3-1. Melting furnace

- Set up a furnace of the more than 3 tons.

- If the type of melting capacity increase in existing furnaces, or when changing heat source or the internal structure.

- 3-2. Chemical facilities

- New furnace with more than 3 tons

- When creates or transfers special chemical facility dealing with a standard amount or higher;

- 기If a special chemical facility is replaced, changed or added to increase production

- Heat-response device

- What is Special Chemical Facility?

- - Equipment that distills, rectifies, evaporates, extracts, etc

- - Facilities operated when the temperature of the heating material is higher than the temperature or point of ignition of the heated hazardous substances.

- - Facilities where hazardous substances may occur due to abnormal chemical reactions such as reaction explosion

- - Facilities operated at high temperature (350 °C) or high pressure (980 KPa)

- - Heater furnace or heater

- 3-3. Drying equipment

- Based on the heat source, the maximum fuel consumption is 50 kg or more per hour, or maximum power consumption of 50kW or more, when the following facilities are installed, moved, or changed

- - In case of drying organic chemical substances contained in the dry mater

- - In case dust is generated by integrated combustible powder of dry

- 3-4. Gas welding apparatus (Fixed)

- Installation, transfer, and change facilities that flammable gas set is more than 1000 kg;

- If the existing gas welding apparatus changes its capacity or its mains

- 3-5. Hazardous substances subject to authorization and management and facilities related to dust work (local ventilation system)

- Local ventilation system(excluding mobile devices) installed for sealing and removing sources of gas, steam or dust from 49 types of materials subject to safety inspection, when installing, transferring, and changing airtight facilities and the entire ventilation system (the amount of exhaust air for local exhaust ventilation and the entire ventilation system is over 60m3/min)

- Local ventilation system(excluding mobile devices) installed for sealing or removing gas, steam, or dust sources from the licensed or managed materials other than 49 types of materials subject to safety inspection (excluding mobile devices), When installing, transferring or changing airtight facilities and ventilation systems (the amount of exhaust air for local exhaust ventilation and the entire ventilation system is over 150m3/min)

- Safety Inspection Targets(49 types)

- Dianisidine and its salts Dichlorobenzidine and its salts/ Beryllium / Benzotrichloride / Arsenic and inorganic compounds, / Asbestos / α-naphthylamine and its salts / Vinyl chloride / o-Tolidine and its salts / chromium ore / Zinc chromate / Nickel subsulfide / Coal tar pitch volatiles / 2-Bromopropane / Cr Ⅵ compounds / Lead and inorganic compounds / Normal hexane / Nickel / Dimethylformamide / Benzene / Carbon disulfide / Cadmium and compounds / Luen-2, 4-Diisocyanate / Trichloroethylene / Formaldehyde / methylchloroform(1,1,1-trichloroethane) / Grain dust / Manganese / Methylene Diphenyl Diisocyanate(MDI) / Musupthalsin / Methyl Bromide / Mercury / Styrene / Cyclohexanone / Aniline / Acetonitrile / Zinc(zinc oxide) / Acrylonitrile / Acrylic amide / Aluminum / Dichloromethane(methylene chloride) / Welded fume / Glass silicic acid / Cobalt / Chromium / Talc / Toluen / Aluminum sulfate / hydrosulfide

- Acceptable substances

- ①Dichlorobenzidine and its salts, ②α-naphthylamine and its salts, ③Zinc chromate, as Cr, ④o-Tolidine and its salts, ⑤Dianisidine and its salts, ⑥Beryllium & compounds, ⑦Arsenic and inorganic compounds, as As, ⑧Chromite ore processing(chromate), as Cr, ⑨volatile Coal tar pitch , ⑩Nickel subsulfide, as Ni, ⑪Vinyl chloride, ⑫Benzotrichloride, ⑬ ①~⑪ any preparation containing substances equivalent to any one of the substances (except the substance that the proportion of the weight is less than 1%) / ⑭ preparation containing ⑫ substances(except the substance that the proportion of the weight is less than 0.5%) / ⑮Other hazardous substances designated by the Minister of Employment and Labor through review by the Industrial Accident Compensation Insurance and Preventive Review Committee as health hazards.

- Hazardous Substances Types under management

- Rules on Industrial Safety and Health Standards [Appendix 12]

- Types of dust work

- Rules on Industrial Safety and Health Standards [Appendix 16]

- 4. Submission documents [Appendix 1] Drawings and documents of Harmful and Hazard Prevention Plan (Relevant to Article 4)

- 1. Drawings and documents according to Article 121 Clause 1 sub clause 5 of the Regulation

| Drawings and Document | Major details to be included in drawings and documents |

|---|---|

| Business outline | Details according to Annex No. 3 form |

| Data on manufacturing processes and machinery and facilities |

A. Piping & Instrument Diagram, P&ID ※ Limited to the piping handling hazardous substances in Annex 1 of the Safety and Health Rules. B. Form from Annexes 4 to 8. C. Electrical drawings, such as electrical open circuit diagrams and grounding plans (including electrical protection devices) ※ It is allowed to omit to submit the electrical circuit diagrams of the water supply facilities that fall within the scope of pre-use inspection pursuant to Article 63 of the Electricity Business Act D. Separation of explosion hazard locations E. Annex 9 form or risk assessment result F. Matters concerning the plan for emergency measures such as fire, explosion, and leakage of hazardous materials ※ Restrict the hazardous substances in Annex 9 of the Safety and Health Rules to workplaces that manufacture, treat or store more than the standard amount. |

- 2. Drawings and documents according to Article 121 Clause 2 sub clause 3 of the Regulation

- A. Melting Furnace

| Drawings and Document | Major details to be included in drawings and documents |

|---|---|

| Business outline | Details according to Annex No. 3 form |

| Attached Facilities Drawing |

A. Structure and layout drawings of major attached facilities B. Copy or drawing of the product catalog for protection devices or protective equipment installed in the furnaces and major attached facilities. |

| Process and Equipment Data 료 |

A. Process Flow Diagram, PFD B. Separation of the explosion hazard location and Annex No. 6 form C. Specifications for the furnace ※ Includes operation conditions such as sort, type, capability, manufacturer and manufacturing year, heating method (type of heat source), standard (maximum) input, temperature, and pressure. D. Types and properties of metals or other minerals treated E. Control procedures and countermeasures in case of emergency, such as leakage of melt and explosion of water vapor |

- B. Chemical equipment

| Drawings and Document | Major details to be included in drawings and documents |

|---|---|

| Business Outline | Details according to Annex No. 3 form |

| Attached Facilities Drawing |

A. Structure and layout drawings of major attached facilities B. Copy or drawing of the product catalog for protection devices or protective equipment installed in the furnaces and major attached facilities. |

| Process and Equipment Data |

A. Process Flow Diagram, PFD B. Piping & Instrument Diagram, P&ID C. Appendix 5 form D. Classification of explosion hazard and Appendix 6 form E. Appendix No. 8 form F. Annex No. 10 form G. Emergency plan such as fire, explosion, and leakage of hazardous materials |

- C. Drying Equipment

| Drawings and Document | Major details to be included in drawings and documents |

|---|---|

| Business outline | Details according to Annex No. 3 form |

| Attached Facilities Drawing |

A. Structure and layout drawings of major attached facilities B. Copy or drawing of the product catalog for protection devices or protective equipment installed in the furnaces and major attached facilities. |

| Process and Equipment Data |

A. Process Flow Diagram, PFD B. Classification of explosion hazard and Appendix 6 form C. Drying Equipment Specifications ※ Includes operation conditions such as sort, type, capability, manufacturer and manufacturing year, heating method (type of heat source), standard (maximum) input, temperature, and pressure. D. Types and Characteristics of Drying Equipment E. Structure, material and performance of ventilation, temperature measuring devices, and other major attached equipment F. Drawings for electrical installations and for electrostatic removal ground |

- E. Hazardous substances subject to approval and management and facilities related to dust work

| Drawings and Document | Major details to be included in drawings and documents |

|---|---|

| Business outline | Details according to Annex No. 3 form |

| Attached Facilities Drawing | Copy or drawing of the product catalog for protection devices or protective equipment installed in the furnaces and major attached facilities. |

| Process and Equipment Data |

A. Process Flow Diagram, PFD B. Classification of explosion hazard and Appendix 6 form C. Sort, type, capability, manufacturer and manufacturing year of the equipment D. Structure, material and performance of other major attached facilities E. Appendix 5 form F. Appendix 7 form |

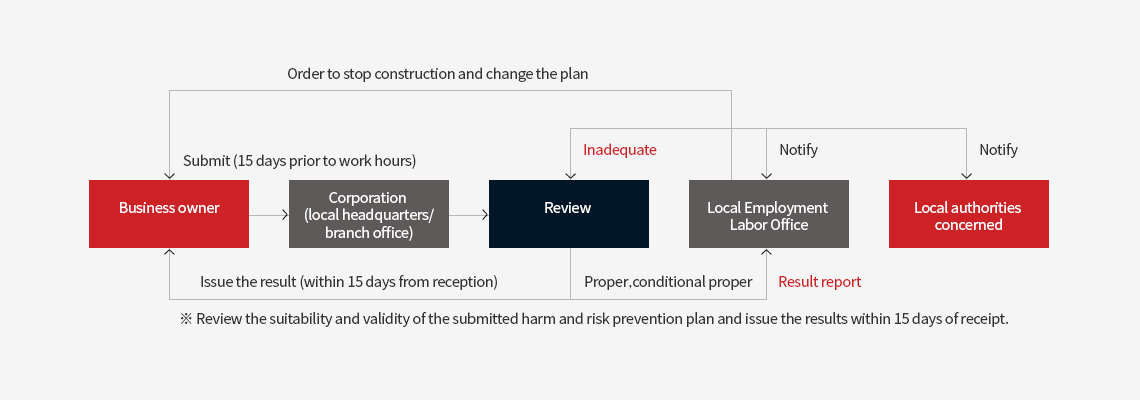

- 5. When and how to submit

- Submission period: 15 days before work begins

- Where to Submit the Plan and Deposit the Fee

- Submission: Local headquaters of Health and Safety Corporation

- Deposit account: Virtual account number is displayed when applying for the plan review

- 6. Review and Confirmation procedures

- Review procedures

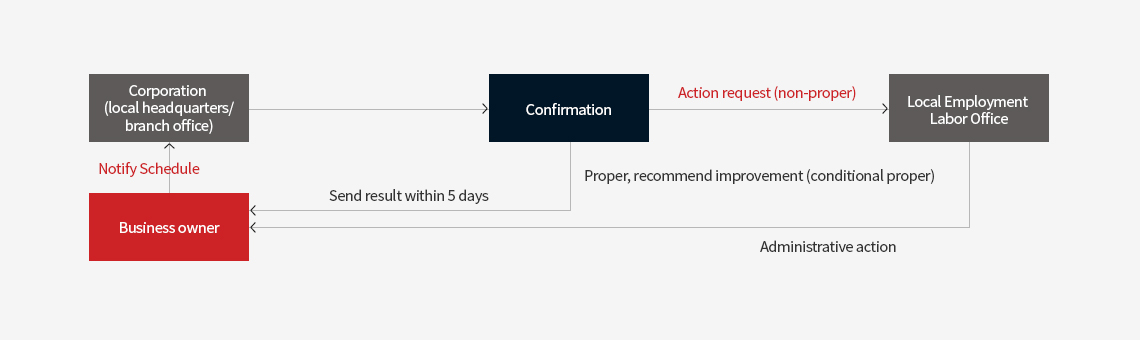

- Confirmation procedures